Aircraft metal fiber filtration is one of the greatest advancements in the aviation industry. Aircraft filtration is a non-negotiable for an aircraft’s safety, performance, and passenger comfort, but it has a long and complicated history. Air filtration technology is not static and is still undergoing advancements to this day.

Aircraft metal fiber filtration is one of the greatest advancements in the aviation industry. Aircraft filtration is a non-negotiable for an aircraft’s safety, performance, and passenger comfort, but it has a long and complicated history. Air filtration technology is not static and is still undergoing advancements to this day.

In today’s blog, we will outline the latest innovations transforming aircraft filtration and how they affect the Houston aviation industry. If you are looking for aircraft metal fiber filtration, contact Global Filtration today!

Why Aircraft Filtration Matters

Aircraft filtration is crucial to any aircraft, no matter the type or application. It has a variety of uses, one of which is engine protection. Filters prevent foreign objects, dust, debris, and contaminants from entering the engine, which can lead to a catastrophic failure. Filters also help with cabin air quality. They eliminate allergens, pollutants, bacteria, and viruses to make the air clean and breathable for passengers and crew members.

Aircraft filtration also helps the hydraulic and fuel systems by protecting sensitive components from particle contamination, ensuring reliable operation, and preventing system failures. It maintains optimal operating temperatures and prevents dust accumulation on electronic devices. Lastly, proper aircraft filtration contributes to fuel efficiency, reduced wear and tear, and extended lifespan of certain components.

The Challenges of Traditional Filtration

Before aircraft metal fiber filtration, we had older fiber media that is now considered less efficient, prone to clogging, and less durable. Some of these include cellulose fibers and fiberglass. This may seem fixable by replacing the media frequently, but this leads to increased downtime and labor costs. Constant replacement also harms the environment by creating more waste, and most of these materials are not biodegradable. Lastly, as aircrafts become more complex, regulations are stricter and require more sophisticated filtration solutions.

Aircraft Metal Fiber Filtration and Other Innovations

Aircraft Metal Fiber Filtration

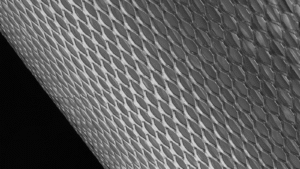

Aircraft metal fiber filtration involves using filters constructed from compressed metal fibers, usually stainless steel, to remove contaminants. Metal filtration offers superior performance compared to traditional filter media like glass fiber, providing enhanced durability, higher filtration efficiency, and resistance to harsh conditions.

Metal fibers are strong and don’t break down easily. They are also resistant to shedding, which is a common problem with glass and cellulose fibers. Aircraft metal fiber filtration is also able to withstand high temperatures, pressures, vibrations, and demanding environments.

Metal fiber filters are crucial for maintaining the cleanliness and reliability of aircraft hydraulic systems, which power flight controls, landing gear, and other critical components rely on. It can also be used to filter fuel, preventing contaminants from reaching the engine, and is used in various other fluid systems within aircraft, ensuring optimal performance and safety.

Nanotechnology in Filters

Nanotechnology is the science of manipulating materials at the atomic and even molecular levels. In other words, working with matter on an incredibly small scale. In terms of aircraft filtration, nanotechnology can enhance a filter’s performance by using nanomaterials to capture extremely small particles, providing superior filtration and sometimes extending filter life. Nanomaterials are especially good at trapping viruses, which is important in today’s climate. Nanomaterials are usually used in cabin air filters, engine intake filters, fuel filters, and more.

Self-Cleaning and Regenerative Filters.

Self-cleaning filters automatically remove debris without manual cleaning, usually using mechanisms like backwashing, scraping, or continuous flushing to maintain efficiency. Backwashing refers to the process of reversing the flow of water, dislodging trapped debris and contaminants, and flushing the system. Scraping involves a mechanism that removes accumulated debris from the element’s surface. Continuous flushing is self-explanatory.

The biggest benefit of self-cleaning filters is their longevity. They significantly extend the life of filters, reduce maintenance, and require fewer replacements. However, they do come with challenges, most notably their complexity of design and the energy consumption of regeneration.

Advanced Material Science

In recent years, there has been a development of new composite materials, specialized polymers, and ceramic matrices for filter media. These offer enhanced durability, resistance to extreme temperatures and chemicals, antifouling properties, and a lighter weight. Some examples of this type of filter include PTFE membranes, advanced fiberglass composites, and porous composites. These materials offer improved performance in harsh environments and greater longevity.

Smart Filtration Systems

Smart filtration systems integrate sensors, data analysis, and often interconnectivity to monitor and optimize the filtration processes in real time. With this technology, you can get pressure differential monitoring, particle count analysis, moisture detection, and so much more. This can help with connectivity by integrating the aircraft’s avionic systems and cloud-based maintenance software to provide predictive maintenance, optimized replacement schedules, reduce unscheduled downtime, and provide data-driven insights into system health.

Sustainable Filtration Systems

For those who want to prioritize environmental responsibility, sustainable filtration is a great option. These are usually made of biodegradable materials and recyclable filter components, which can help reduce waste. This can help you lower your carbon footprint, reduce landfill waste, and help you align with airline sustainability goals. It does come with challenges, as balancing sustainability with performance requirements can be tricky.

Tangible Benefits of These Innovations

Why are all of these advancements so revolutionary? They allow for more reliable operation and reduce the risk of engine failure and system malfunction. Fuel efficiency is also improved, as lower pressure drop across filters means less engine strain.

Advanced filtration technology can help reduce the need for maintenance, which in turn reduces cost and downtime. Longer filter life, predictive maintenance capabilities, healthier air, greater passenger comfort, and contribution to greener aviation are all added benefits as well.

The Future Outlook for Aircraft Filtration

We may see further advancements with the integration of AI technology, machine learning, and the development of new materials. We may see even better efficiency, greater sustainability, and fully autonomous monitoring as well. In the long term, we expect aircraft filters to be a self-managing component of the aircraft ecosystem.

Choosing the Right Aircraft Metal Fiber Filtration Partner

Who should you choose as your aircraft metal fiber filtration supplier? Choose someone who has a deep understanding of advanced technologies and has a wide range of innovative filtration products and expert consultation services. Luckily, Global Filtration checks all of those boxes! If you need help with aircraft metal fiber filtration, give us a call today!