Effective Hydraulic Fluid Filtration for All Types of Aircraft

Aircraft use hydraulic systems for key functions like moving flight controls, lowering landing gear, and applying brakes. These systems rely on hydraulic fluid to transmit force and ensure all mechanisms operate smoothly. Contaminants in hydraulic fluid can damage pumps, valves, and actuators, causing malfunctions and putting flight safety at risk.

Aircraft use hydraulic systems for key functions like moving flight controls, lowering landing gear, and applying brakes. These systems rely on hydraulic fluid to transmit force and ensure all mechanisms operate smoothly. Contaminants in hydraulic fluid can damage pumps, valves, and actuators, causing malfunctions and putting flight safety at risk.

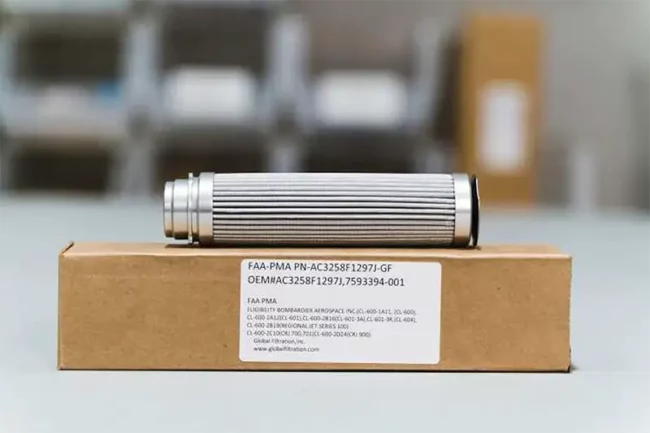

Global Filtration offers advanced aircraft hydraulic filtration products that outperform older designs. Our PMA-certified filters use innovative metal fiber filtration technology to remove more contaminants. This results in better performance, longer component life, and reduced maintenance costs for your fleet.

Reduce Contaminants in Hydraulic Fluid with Metal Fiber Filters

Traditional microfiberglass hydraulic filters have a significant drawback: they can actually introduce contaminants into the very fluid they’re supposed to clean. The tiny glass fibers that make up these filters can break down and shed particles, adding to the contamination problem.

Metal fiber filtration is a superior solution. These filters are constructed from metal fibers, typically stainless steel, that are resistant to shedding and breakdown. The sintered fibers provide highly effective filtration that is able to capture a wider range of contaminants, including those that microfiberglass filters might miss. Metal fiber filters can also be cleaned and reused multiple times. This not only reduces waste and environmental impact but also saves costs in the long run by minimizing the need for frequent filter replacements.

Aircraft Hydraulic Filters

Effective aircraft hydraulic filters help maintain the safety and reliability of all types of aircraft, from small general aviation planes to large commercial jets.

Commercial and regional aircraft have complex hydraulic systems with multiple circuits for redundancy. They usually operate at higher pressures (3,000 PSI or more) and use fire-resistant hydraulic fluid. Redundancy systems are also in place to ensure that if one system fails, there’s a backup ready to go.

Corporate jets tend to have simpler hydraulic systems than commercial airliners, but they still rely on them for essential functions. They might operate at slightly lower pressures and may or may not have multiple redundant systems depending on the aircraft’s size and design.

General aviation aircraft, like single-engine planes, often have simpler, lower-pressure hydraulic systems. They might use a single hydraulic circuit for basic functions like brakes or retractable landing gear.

Rotorcraft use hydraulics for flight control and other functions like rotor blade adjustments and winches. Their systems often operate at lower pressures than those found in large airplanes, and the design varies depending on the helicopter’s size and purpose.

Hydraulic Fluid Filter Media for Military Aircraft

Military aircraft, especially helicopters, often operate in harsh and demanding environments, and this can accelerate the contamination of hydraulic fluids. Choosing the right hydraulic fluid filtration is critical for maintaining operational readiness. Reliable, efficient filtration ensures that flight controls, weapons systems, and other essential hydraulic components continue to function properly.

Your Source for Advanced Aircraft Filtration Products

As a PMA-certified manufacturer, Global Filtration offers a comprehensive range of advanced filters for all aircraft types. We’ve been specializing in innovative aircraft filtration since 1995. Contact our team for all your filtration needs.