Aerospace demands relentless perfection, making finding accurate filtration solutions paramount in order to support each system’s delicate hydraulics. Aircraft filters are required to operate under extreme pressures and rapid thermal cycling, all while controlling critical aspects of flight operations. The primary issue that these filters face is related to heat, as it is the most common reason for fluid degradation within an aircraft’s hydraulic system. Because of this, Global Filtration is known for using reliable, durable, and cost-effective metal fiber materials for our aircraft filtration solution design process. Use this blog as your guide to learning about what makes metal fiber the most high-performance aircraft filtration solution and how it eliminates microscopic fluid contamination.

Aerospace demands relentless perfection, making finding accurate filtration solutions paramount in order to support each system’s delicate hydraulics. Aircraft filters are required to operate under extreme pressures and rapid thermal cycling, all while controlling critical aspects of flight operations. The primary issue that these filters face is related to heat, as it is the most common reason for fluid degradation within an aircraft’s hydraulic system. Because of this, Global Filtration is known for using reliable, durable, and cost-effective metal fiber materials for our aircraft filtration solution design process. Use this blog as your guide to learning about what makes metal fiber the most high-performance aircraft filtration solution and how it eliminates microscopic fluid contamination.

The High-Stakes Environment of Aircraft Hydraulics

Before understanding the specific breakdown process that makes metal aircraft filtration solutions so integral, it is essential to understand the unique conditions that cause hydraulic fluids to exceed their limits. Hydraulic systems and the fluid they transport face two primary types of stress:

- Mechanical stress

- Thermal shock

By understanding these common operational stressors, you can feel more confident in working with Global Filtration and making the switch to metal filters for your fleet.

The most imperative opening stress that hydraulic systems face is temperature extremes, meaning they are constantly facing both high ambient temperature, as well as localized hotspots where temperatures could soar. Usually, these hotspots can be found in heat hubs, such as near pumps or valves, where friction is high. Additionally, high operating pressures can also accelerate fluid breakdown cycles—a phenomenon called shearing—which quickly causes systems to fail.

This chemical degradation is typically what marks the official end of a fluid’s life in most industrial settings. Surprisingly, it isn’t because of the viscosity change, but instead because of the breakdown of each molecule that changes everything about its movement.

Decoding Thermal Breakdown and Filtration Solutions

Thermal breakdown isn’t a sudden, unexpected event, but instead a slow, step-by-step reaction to exposure to both heat and oxygen within the hydraulic system. When thermal stress occurs, it begins the fluid breakdown immediately, oftentimes resulting in one or both of the most common outcomes:

- Formation of corrosive acids

- Production of insulating, performance-blocking varnish

The formation of corrosive acids typically starts with the fluid molecules reacting with dissolved oxygen. To make matters worse, heat nearly always rapidly accelerates this process. As the fluid is exposed to oxygen, it begins to form peroxides and free radicals, which gradually eat away at key aspects of your aircraft filtration system.

As breakdowns continue to worsen, they can lead to outcomes such as reduced thermal transfer efficiency, sticky valves, slow response times, and increased wear rates due to poor lubrication.

From there, the fluid can begin creating a sticky, insoluble residue known as varnish or sludge. As this continuously builds up, it will start to actively affect key aspects of your system, including seals and internal metallic surfaces. Because of this, the Global Filtrations team of engineers and aircraft filtration experts designs and manufactures innovative, PMA-certified metal fiber aircraft filters that help solve the prevalent issue of thermal breakdown.

How Metal Fiber Aircraft Filters Offer A Modern Solution

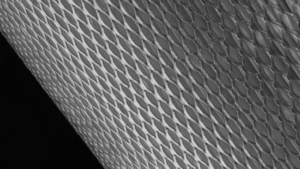

Now that you understand how fiberglass or mesh aircraft filtration systems can make a huge impact on the well-being of your system as a whole, it is vital to learn how metal fiber filters can make a positive difference. When it comes to high-temperature applications, like the majority of aircraft internal systems, filters need to be equally as durable and reliable as the mechanisms they support. Because of this, using metal fiber media, typically made from stainless steel, can help by providing a highly controlled filter that offers increased strength and thermal stability.

The biggest advantage of using metal filtration solutions instead of typical media, such as microglass, is the structural integrity it offers. We can often eliminate the passive voice by focusing on the assumed agent or process that created the structure. The sintered structure of the metal filter helps prevent media migration or pore size change when exposed to differing pressure or intense vibrations.

Finally, metal aircraft filters are fully resistant to thermal damage, unlike the vast majority of common media materials. This not only helps protect your system from mysterious shutdowns and downtime, but also leads to lower replacement costs and improved reliability.

How Metal Filters Lead To Thermal Breakdown Prevention

Although the structural superiority of metal aircraft filters is evident, the direct benefit is their ability to eliminate thermal breakdown by captured sub-micron-sized particles that ignite this damaging process. Simply put, this media category does much more than just filter fluid; it actively prevents chemical corrosion from negatively impacting your aircraft’s delicate hydraulic system.

The first way it does this is through its targeted removal design. The specific shape and size of the filter is extremely fine, but also strong – this allows it to actively capture the smallest types of metallic particles that will start the thermal breakdown chain of events.

The rigid metal filter system locks captured particles and debris in place, preventing slippage from force or release back into the system, even under high pressure or thermal stress.

The performance and results of metal filtration solutions are measured through what engineers at Global Filtration and other companies call a Beta Ratio. This ratio is a vital metric that illustrates the accuracy and dependability of an aircraft filter. A high Beta Ratio means that for every 2,001 particles reaching the filter head, only one escapes. A high variable, characteristic of metal filters, protects your system from even the smallest, most damaging particles that contribute to thermal breakdown, thereby significantly extending your fluid’s life over time.

The System-Wide Benefits of Metal Aircraft Filters

While the Beta Ratio measures the micron stability, the benefits of using metal aircraft filters go much further. The biggest benefit, aside from the thermal breakdown resistance, is the individual component protection, meaning that by reducing particle contamination and varnish formation, you can ensure high performance for even the most sensitive components.

Additionally, metal fiber filters can offer an assortment of operational savings, including:

- Extended fluid life: When you prevent chemical reactions and corrosion, your fluid will stay cleaner and chemically viable for longer.

- Reduced unscheduled maintenance: This brings a lower risk of sticky valves and slow performance, as well as high replacement fees due to reactive maintenance.

- Lower life cycle costs: Although metal fiber aircraft filters have a high upfront cost, they last longer, require fewer maintenance expenses, and provide more consistent service.

Finally, because of these savings, as well as the structural stability, metal fiber filtration solutions can help offer predictable and highly durable flight control system operation.

Securing Hydraulic Reliability through Metal Filtration Solutions

Now that you understand the high-stakes nature of hydraulic systems and how thermal breakdown can lead to poor operation and high repair costs – the clear choice for improved reliability is metal fiber filters. At Global Filtration, our FAA-Certified metal filtration solutions offer the highest level of durability and hydraulic system protection. Contact us today for a free estimate on a metal fiber filtration solution.