Improved Efficiency and Cost Savings - Metal Fiber Filtration

Standard Microfiberglass Filters: 1940s Technology

For decades, the aviation industry has relied on microfiberglass filters, a technology dating back to the 1940s. However, these filters come with limitations. The fine glass fibers are prone to shedding particles, which contaminate hydraulic fluid and can lead to system damage or failure. Additionally, microfiberglass filters can be susceptible to chemical breakdown from exposure to certain fluids and contaminants. They may also struggle in extreme temperatures and can become less efficient over time.

Although still in use, this older technology may not be the best solution for modern aircraft with increasingly demanding performance requirements and tighter safety margins. Advancements in filtration technology offer improved performance and reliability for this critical component.

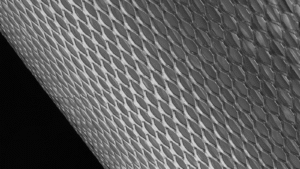

Metal Sintered Fiber Traps All Hydraulic Contaminants

Sintered metal fiber is a significant leap forward in filtration technology. These filters are constructed from fine metal fibers, typically stainless steel, that are sintered together to form a strong, porous structure. The tightly controlled pore size distribution of sintered metal filters ensures that even the smallest contaminants are efficiently captured. This includes microscopic wear particles, dirt, dust, and other debris that can cause damage to sensitive hydraulic components.

The nature of the metal also makes it highly resistant to fatigue, chemical breakdown, and extreme temperatures. This allows the filter to deliver consistent performance and gives it a longer service life compared to traditional filters. According to one case study, after switching to metal fiber filters, a US helicopter operator saw filter failures drop by 90% and the time between failures increase significantly.

Metal Fiber Filters are Cleanable and Reusable

One of the significant advantages of metal fiber filters is their reusability. Unlike traditional disposable filters, metal fiber filters can be cleaned and reused multiple times.  Cleaning typically involves backflushing with a compatible solvent or using an ultrasonic device to remove contaminants. This process can be repeated 4 or 5 times in total, reducing the need for frequent replacements and resulting in more cost savings over time.

Cleaning typically involves backflushing with a compatible solvent or using an ultrasonic device to remove contaminants. This process can be repeated 4 or 5 times in total, reducing the need for frequent replacements and resulting in more cost savings over time.

Metal Fiber Filtration for Defense Rotocraft

Military helicopters need to maintain peak performance under extreme conditions. Advanced metal fiber filters significantly reduce contamination in critical hydraulic systems such as flight controls and weapons systems. Metal fiber filters also withstand harsh environments and severe vibration better, reducing maintenance needs and improving readiness timelines.

Get a Quote for Updated Metal Fiber Filters

Upgrade your hydraulic filtration system with advanced metal fiber filtration products for your fleet. Experience the benefits of superior performance, longer lifespan, and reduced maintenance costs. Contact us for a custom quote now.